Let’s see how it works

Prototyping is an indispensable step in the process from idea to market-ready product. There are several reasons to develop prototypes. Firstly, to test and validate how a functionality that works digitally in design also demonstrates its effectiveness in practice. Additionally, to create a fully functioning demonstrator that gives stakeholders and investors tangible proof that this product innovation is set to conquer the market. Only when crucial factors such as functionality, design, and composition have been demonstrated, can the final (and costly in the lead-up) production process be launched on a large scale.

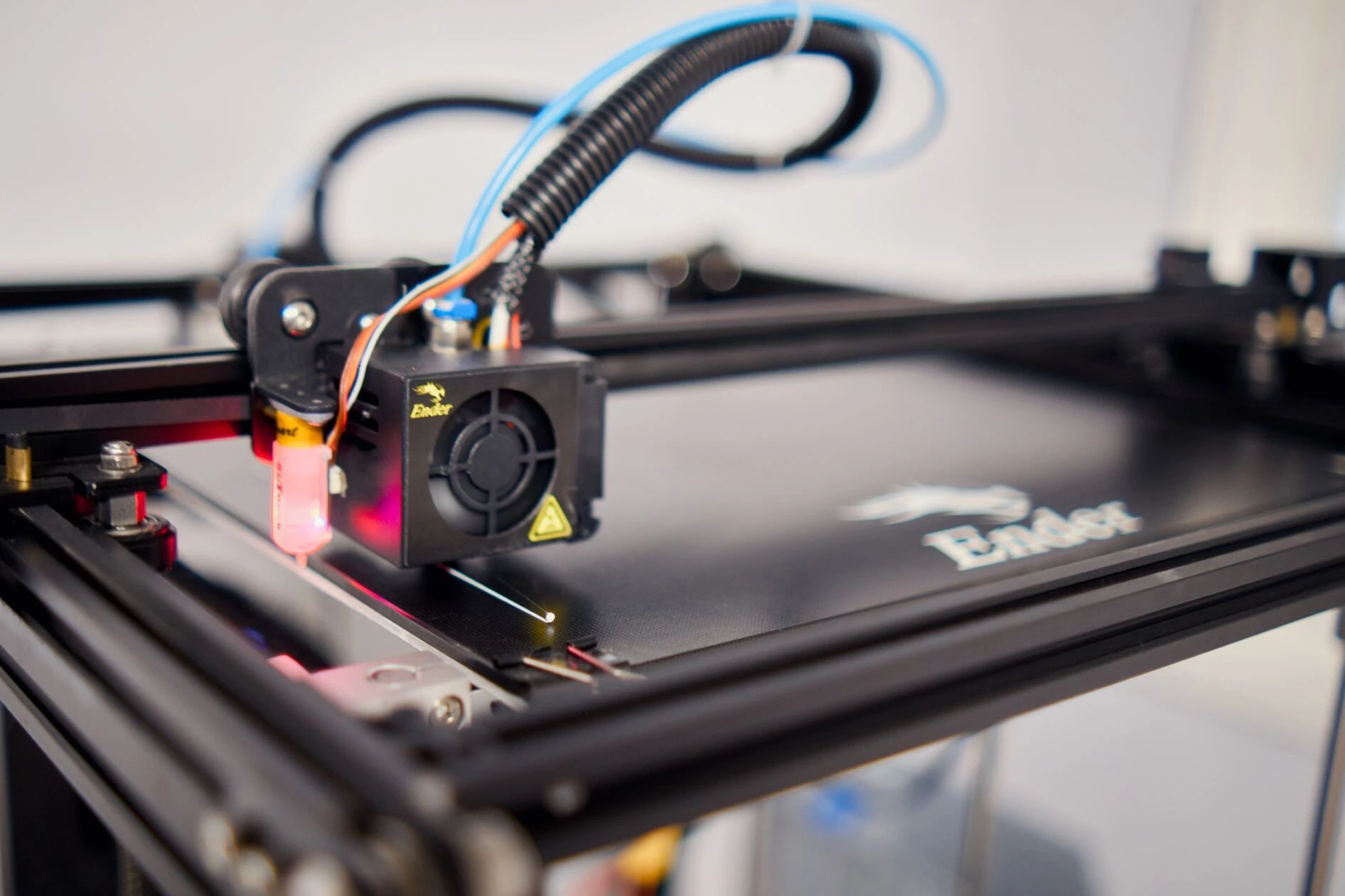

In the PEZY Protolab, we develop the initial tangible versions of a product. Once the basics have been tested, we can utilize our own PEZY Plastics Factory, where we have access to a complete toolshop with 3D printers, mold making facilities, injection molding machines, and various testing and finishing tools. Here, we test and validate with prototypes that closely match the desired end result. In our PEZY Plastics Factory, we also have tools for metalworking and build complete prototypes and small series, incorporating not only plastic components but also other parts made from metals and upholstery.