There’s a PEZY factory for that

The process from engineering to a tangible product is time-consuming. Testing, validation, adjustments, and modifications are necessary. Designers and engineers often face challenges in accessing this knowledge, which is why we invest in our own production facilities and have strategic collaborations with manufacturers specialized in small-scale production.

For plastics, prototypes, and small series, we have our own PEZY production facilities in the Netherlands. These testing and production locations provide us and our clients with control over the process and progress.

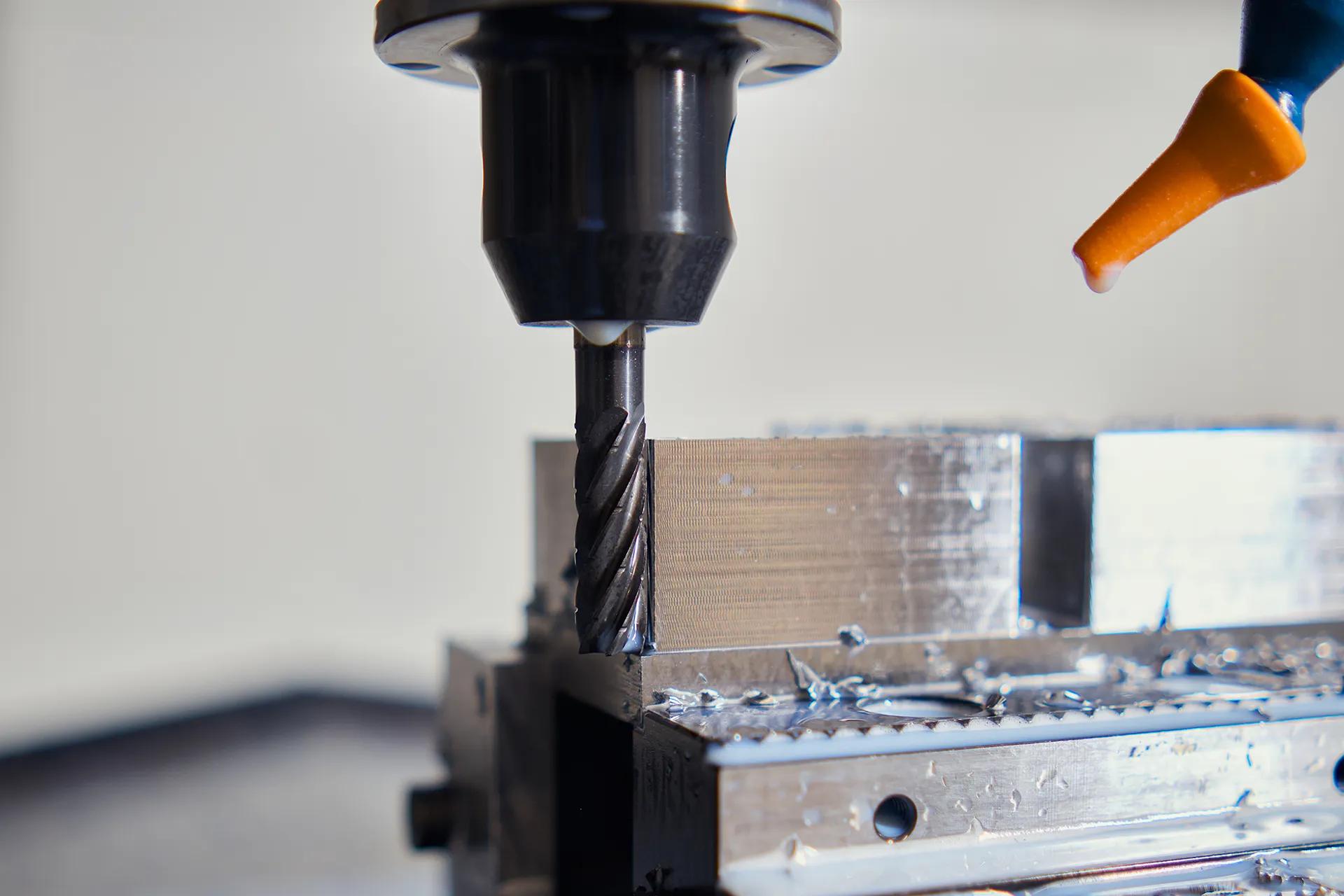

The PEZY Plastics Factory in Groningen is a fully equipped plastics factory with a state-of-the-art machine park. We have the capability to go from a digital prototype to tangible, high-quality components, from single pieces to small series, all under one roof.

Having more control

In the pre-development phase of product development, many challenges can be identified and addressed, but issues may still arise during production. Our production experts have a wealth of knowledge and expertise in material properties, production techniques, and we have a complete tool shop with 3D printers, mold-making facilities, injection molding machines, welding facilities, and various testing and finishing tools.

Make it work

The PEZY Factory, as a production facility, allows us to prototype and iterate on the job, something that is not typically offered by large-scale injection molding companies. We believe in the power of Rapid Market Validation, and this facility plays a significant role in that. Our adaptability and problem-solving capabilities have helped many brands tackle issues early on before large-scale production runs.